Closed Containment RAS, The Key To Sustainably Raised Salmon

Closed containment salmon farming "does no harm" to our local environment.

Do No Harm

As Palom members practice organic sustainability in our personal lives and in our corporate lives, our first belief is to “do no harm.” We strive to do no harm to ourselves, to our customers, to our neighbors, and to our environment.

Closed recirculation farming, or RAS, cannot manage itself. Talented people must be involved in all aspects of farming. Palom’s partners have and future staff will have backgrounds in science, fish husbandry, nutrition, microbiology, engineering and finance. But most importantly all will have common sense and an awareness of their surroundings. Technology aside, all those working for Palom must a sense of “what is normal” and “what is abnormal”. “Speak up, ask questions and challenge the status-quo.”

RAS, as we have mentioned on early pages, allows total control of the fish environment, including seawater, light, and feed. Where closed containment shines is in the limits it places on pathogens both entering and leaving the confines of the farm.

RAS has both physical and prophylactic barriers against predators and pathogens.

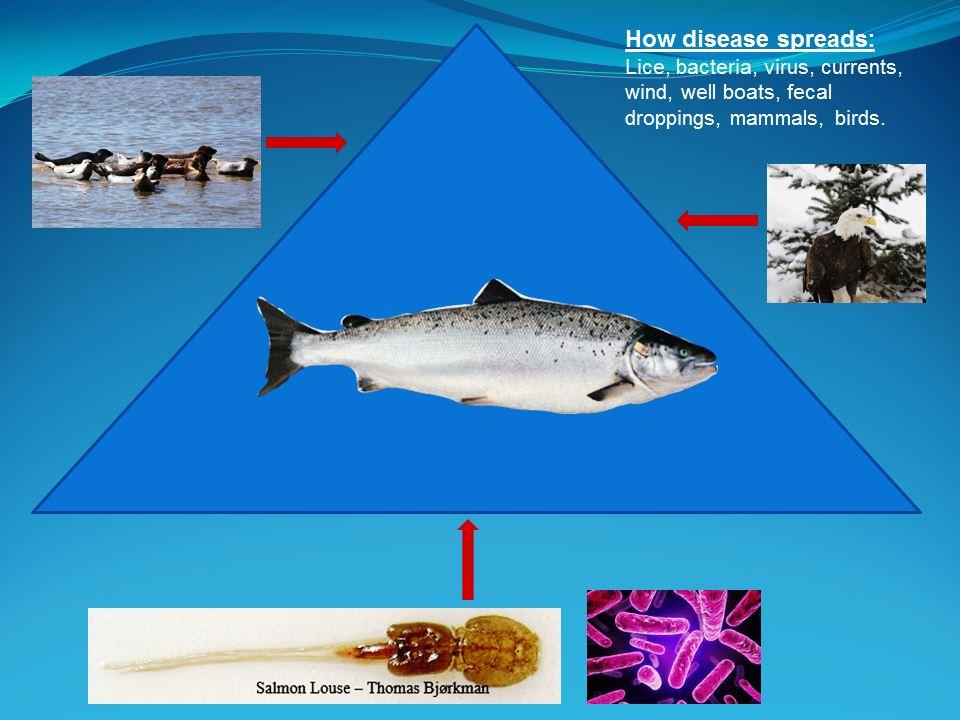

RAS has both physical and prophylactic barriers against predators and pathogens.Disease outbreak within RAS happens far less than Net-Pens simply because RAS have physical barriers such as tanks, walls, and ceilings and RAS purifies incoming water with microfiltration and then disinfects the filtered water with high doses of UV light and ozone. Net-Pens are subject to disease as there are no physical barriers. Infections spread through well boats, currents, predatory birds and migrating fish. Prophylactics are the only weapon available, eliminating the organic market for these fish. In 2017, there is a massive lice infection worldwide costing billions to control and degrading the quality of salmon meat in the conventional market.

Two well know RAS farms experienced outbreaks of Furunculosis. All occurred from entry of personnel and tools from nearby infected sites. Both companies now vaccinate smolt as will Palom. Continuous testing certifies no disease found in both facilities for two full years. Lice have never been a problem.

If disease is present in RAS, the operator may harvest the fish and sell into the conventional market or secondary market like pet food. Crop insurance covers for any deficiency balances.

Large, non-organic, multinational companies are developing RAS both to create super-smolt and salmon grow-out facilities. A super smolt is a baby fish biologically ready to grow in seawater (“smoltified.”) Large companies are strategically limiting mature salmon in seawater due to the inherent risks of disease, predation, and fatal extreme weather. Growing super smolt in RAS, increasing the smolt size from 100 grams to 1,000 grams dramatically reduces mortality in the open net pens. Billund Aquaculture has discussed large RAS projects they are constructing for smolt, super-smolt and salmon grow-out RAS.

Here are hyperlinks to the David Suzuki Foundation and Seafood Choice recommendation of RAS. Both organizations are highly critical of net-pens but also realize that the wild fish supply cannot meet demand, and RAS closed containment is a viable solution.

The Palom Aquaculture website shows large RAS projects in North America and worldwide.

Closed Containment - Conclusion

RAS is a documented system to keep fish free from disease as is not the case of net-pens exposed to mother nature. The few cases of RAS disease have been due to employee error by not following standard prophylactic procedures.