Recirculating Aquaculture Systems - Comparison To Net Pen

Information about recirculating aquaculture systems and net pen systems has been excerpted from a Conservation Fund / SINTEF presentation whose authors include: Trod W. Rosten, Kristian Henriksen, Erik Skontorp Hognes, Brian Vinci and Steve Summerfelt. We include a direct link to the complete presentation below.

Model Land-based Recirculating Aquaculture Systems farm (32 million US $ )

Invested equipment:

- 40,000 m3 of rearing tank volume

- 25,500 m2 of building area

- 2,500 m2 processing facility

- 885 m3/min of pumped RAS flow

- Pumps and Piping

- Screen filters

- Biofilters

- Gas Conditioning Filters

- 1.08 – 1.26 kg feed per m3 supply water

- Feeding Systems

- Backup Generators

Model Net Pen farm (12,3 million US $):

- Two production sites, each with six net pen cages.≈587,000 m3 net-volume

- 120,000 m2 area footprint visible at sea

- ≈179,000 m2 area footprint incl. no thoroughfare zone

- ≈463,000 m2 area footprint incl. no fishing zone

Invested equipment:

- 3 licences

- 12 Floating rings (157m Ø)

- 24 nets (25 m deep)

- 2 mooring systems

- 2 boats

- 2 feed barges (150 Mtons)

- 12 camera systems

- 12 feed distributors

- 12 power systems

Model Land-based Recirculating Aquaculture Systems Farm

- One production site for all life-stages

- Four cohorts per year

- Growth based on thermal growth coefficients from Freshwater

- Institute growout trials, adjusted down by 10%:

- 1.1 for Fry

- 1.25 for Smolt

- 1.8 for Pre-growout

- 2.2 for Growout

- Mortality per generation 16%

Feed conversion ratios:

- 0.75 for Fry

- 0.90 for Smolt

- 1.0 for Pre-Growout

- 1.1 for Growout

- Overall Feed to Whole Fish Produced (kg/kg): 1.09

Rearing Density

- 80 kg/m3 maximum

Harvesting:

- Time from first feeding to first harvest: 21 months

- Harvest every week of the year

- Each cohort harvested over 13 weeks

- One grisle harvest at ~1.2 kg for 50% of males

- Harvest in total: 3947 M.tons LWE, 3300 M.tons HOG (5% purge loss / 12% HOG loss)

- Initial harvest weight (whole fish): 4.5 kg

- Average harvest weight (whole fish): 5.1 kg

- No downtime in the bio-plan

Model Net Pen farm:

- 2 production sites & 3 licences of 780 M.tons of maximum total biomass at sea.

- Two transfers of smolts to sea annually, to one site

- S1 at 1st of April, 100 grams, 520' smolts in three cages

- S0 1st of August, 75 grams, 520' smolts in three cages

- Growth based on the Skretting table, Specific Growth Rate

- (SGR), adjusted down by 12 %.

- Mortality per generation approximately 16,1 % (average in

- Mid-Norway in 2011) (Norwegian Food Safety Authority 2011).

- Economic feed conversion ratio: 1,27 (average in Norway over the last ten years) (Directorate of Fisheries 2013).

Rearing Density

- 25 kg/m3 maximum

Harvesting:

- Time from first feeding to first harvest: 24 - 31 months

- Time at sea before first harvest: 16 months

- Harvest 8 months of the year

- Harvest S1 from July to October

- Harvest S0 from November to February

- Harvest in total: 3 975 M.tons LWE, 3 299 M.tons HOG

- (5 % purge loss /12 % HOG loss)

- Average harvest weight (whole fish) : 4,5 kg

- Two months of fallowing between production cycles

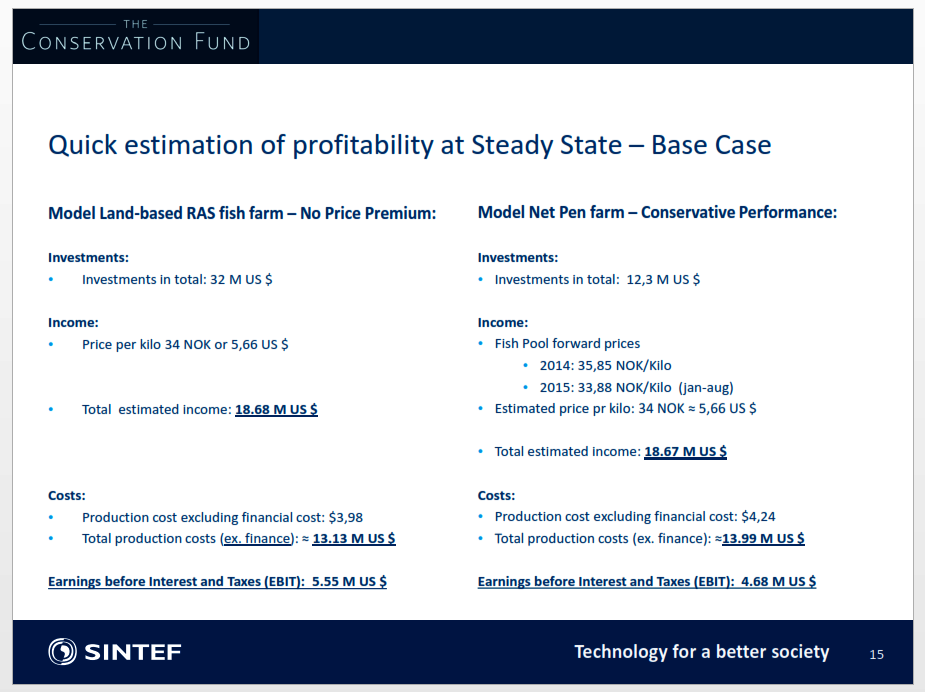

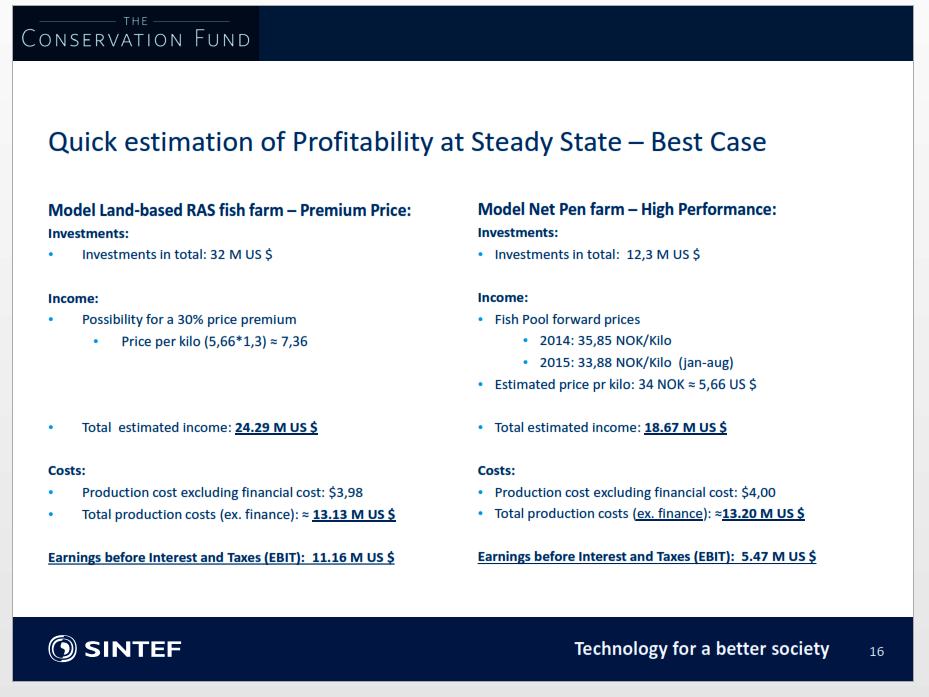

Recirculating Aquaculture Systems Profitability

Complete Presentation (Workshop #6)

- Palom Front Page ›

- Recirculating Aquaculture Systems Pros and Cons ›

- Recirculating Aquaculture Systems Comparisons